Miter saw has long been a familiar tool to woodworkers with how balancing it is between functionality and compatibility.

But can you cut metal with a miter saw? Will the blades enter the dense structure as smoothly as they do to wood, or this is where they meet their match?

Many have questioned this ability of miter saws, yet, few dare to take theirs out for a test drive. Stop trying to stress yourself out with all the guessing.

If you need to see whether miter’s saw teeth have any use against the sharp edge of this material, I have the answer right below.

Can You Cut Metal With A Miter Saw?

As far as I can tell from my experience, the density and tough texture of metallic materials are not something the miter saw’s motor has difficulty handling. That being said, there are certain conditions.

The saw’s blade set is not made for the material, so the very first thing on your hand would be to find some apt replacement.

Note that you must adhere to plenty of rules for safety precaution as well, which we will go deeper in later sections.

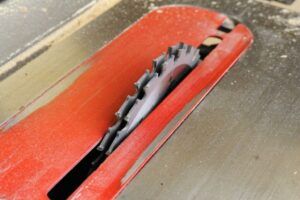

What Blades Should You Use?

While the usual miter saw blades do a wonderful job chopping trims into desired length, them working with metal can pretty much mark the beginning of a disaster.

No surprise here. They are designed with wood in mind, not metal. During their making, no manufacturer has factored in what may come to pass while running their cutting teeth through the materials.

In the end, the speed they function at becomes unsuitable for metalwork.

If your projects require quick and precise cuts on metal right away but there is no better tool at hand, you can temporarily take the wood-cutting carbide blade from the machine and put in an alternative for metal cutting.

Blades designated for metal deliver desired performance

You might have read somewhere on the instruction of your miter saw that it can slide through non-ferrous metal (the soft type like aluminum or copper).

But I personally do not think you should risk it, unless it is a really quick cut. The blade is designated for wood, never metal, after all.

Of course, for ferrous metal containing iron, replacement is a compulsory step.

Thankfully, high-quality metal-cutting blades for both types are available in large numbers. It will not take you long to find something catering to your needs.

Another piece of advice from my experience: Get creative during your shopping.

It never hurts to add a tweak of your own, and a triple-chip grind blade for cleaner cuts or composite blades for various levels of density is always better than the plain old normal circular choice.

What may happen without that blade change?

Miter saws work at a much more overwhelming speed than crafting metal requires, leading to more friction between the blade and the cutting surface.

This can never be a good thing because both your tool and workpiece may end up as hot-red as new welded joints in the process.

Do not take this lightly. The sudden shift in temperature can do quite a number on the metallic structure, so you are in for lots of respiration later on.

Besides, blazing hot tools certainly put more risk into your workstation.

See why moving to a new blade set is the first thing to keep in mind.

Safety Precaution When Cutting Metal With A Miter Saw

As much as a professional craft maker you are, you can find yourself in a tight situation all the time without learning how to properly work on metal using a miter saw.

The material is different from the wood you are used to so it is never unwise to pocket some handy tips.

Safety tips you carry out your task smoothly

Before placing anything underneath the blade, run a fine tooth comb through it to check for any debris that you miss on the last cleaning.

The friction and heat induced in the process are unlike what you experience during woodworking. Failure to clean it properly means no clean cut later.

Only the tool is not enough, scan the ground for leftover wood as well. Since this is metal we are talking about, even when there is no danger of the sharp chips flying around, the risk of sparks remains. Them touching the timber and saw dust can set your entire place on fire.

Another rule of thumb is to work slowly and steadily. Never lower the saw onto the cutting surface until it has reached full speed. The blade can kick back if you keep rushing it.

One final thing, never, ever forget to keep yourself safe with your trusty protective gear set. Better safe than sorry!

Should You Use A Miter Saw For Metal?

I do not deny the fact that with the appropriate blade, miter saw cuts through metal as well as any tools specialized for the task.

However, this does not make it the ideal choice for permanent usage.

For the most part, miter saws’ RPM (revolutions per minute) specifications can be much higher than what you need for metallic materials.

In other words, them coming together will usually get sparks flying, but not in a way that makes you happy, especially since debris will present itself as well.

Getting a metal-cutting blade for a miter saw is also a poor idea budget-wise because it calls for constant replacement.

The saw’s motor will soon go out of shape for all the heat it takes on. Meanwhile, the speed that forces itself on the blade (which lasts less than 250 cuts) will soon dull it.

What I try to say is: It is best to use your miter saw as a metal-handling tool if your job does not demand you to deal with the material on a daily basis.

Otherwise, a specialized machine for the task, such as a chop saw or circular saw. They will be a more worthwhile investment.

Conclusion

A miter saw might not be the most recommended piece of equipment for tough metal, but it is by no means a poor choice.

Get the right blade is in place, and the users adhere to all the safety precautions, anyone can utilize its full potential for the material.

So, can you cut metal with a miter saw? Yes, you can! Just keep in mind that it is only a temporary solution.