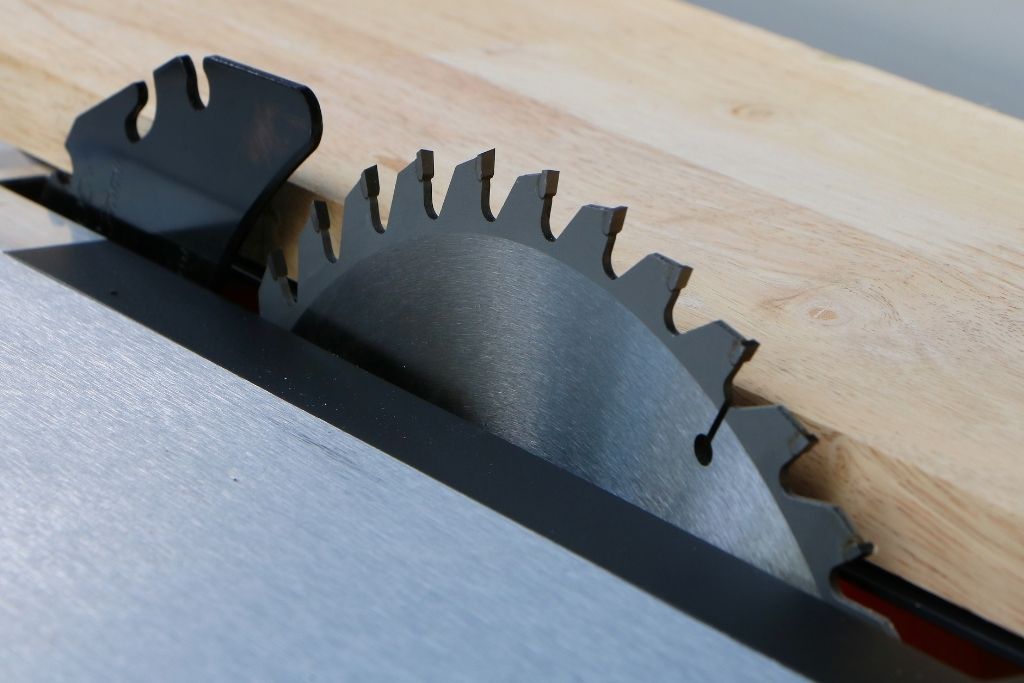

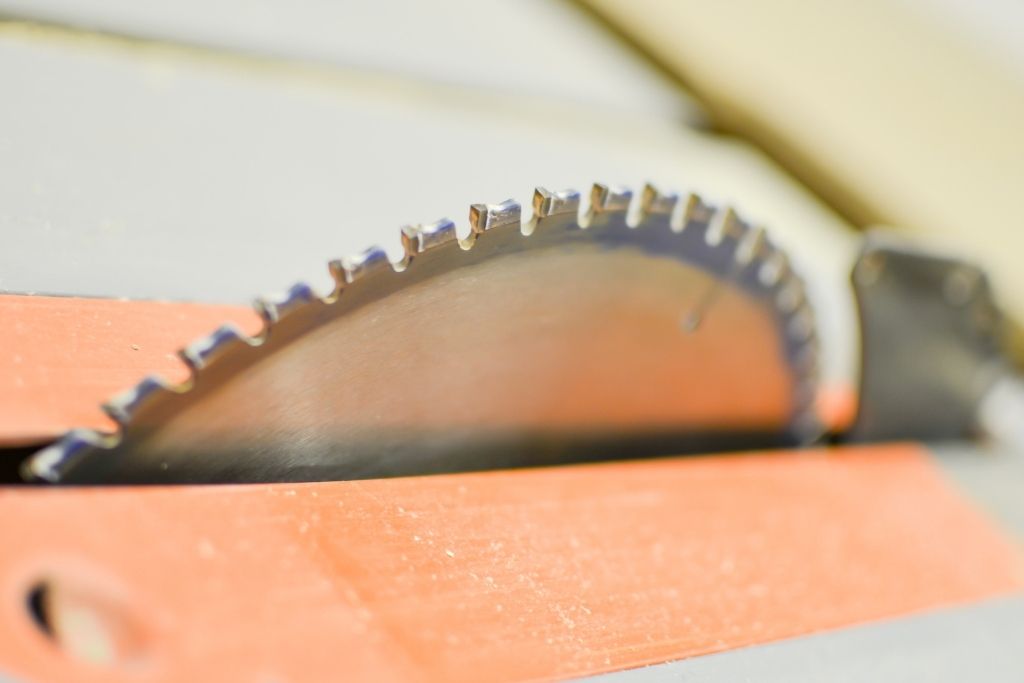

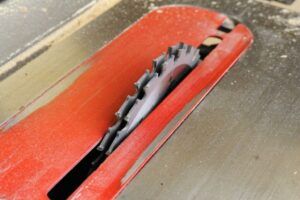

Table saws are among the most common and helpful for woodworking projects. They offer straight lines, rip large workpieces, dado, and various cuts with a degree of precise cuttings.

Yet, the saws cannot complete the jobs without having the best table saw blades.

Let’s dive into this article, learn how to pick up blades that meet your cutting requirements, and our review the top 6 table saw blades.

Table of Contents

- Top Rated Table Saw Blades Comparison

- Types of Table Saw Blades

- 6 Best Table Saw Blades – Reviews

- How To Choose The Best Table Saw Blade

- Tips When Use A Table Saw Blade

- Frequently Asked Questions About Table Saw Blade

- Why Is Table Saw Blade Important?

- How High Should I Set My Table Saw Blade?

- Can I Sharpen The Table Saw Blade?

- How To Sharpen The Table Saw Blade?

- How To Make Dado Cuts With Table Saw Blades?

- How To Change Table Saw Blade?

- Can I Put A 12-inch Blade On A10-inch Table Saw?

- Which Is The Best Way To Clean A Table Saw Blade?

- Conclusion

Top Rated Table Saw Blades Comparison

Types of Table Saw Blades

Table saw blades do not come the same, and they are divided into several groups based on their cutting purposes, shapes, grinds, and teeth.

Crosscut Blades

As its name suggests, the crosscut table saw blades deal with smooth cuts across the wood grain.

They often have more teeth and thinner kerf than the ripping or combination blades at the same width – around 60 to 80 teeth. That to be said, there are fewer gaps between teeth, and the blades remove less material, leaving more precise and cleaner cuts.

In drawbacks, crosscut blades cut more slowly. We would recommend this type for applications that put precision and smooth finishes first.

Flat-Tooth Ripping Blades

Ripping along the grain of stocks is a common task. Thus, everyday woodworkers prefer the ripping table saw blades.

Unlike the crosscut, this second blade type has only 24-30 teeth with large in-between gullets and thicker kerf.

It often goes with anti-kickback teeth behind the carbide tips. As a result, the blades rip the wood fibers quickly and securely. Ripping cuts can leave ragged and tear-out edges, though.

Combination Blades

The combination blades for table saws lie between the crosscut and ripping types, which can handle both applications. The number of teeth is often 30 – 50, coming with either full or thin kerf.

At this rate, the blade cannot produce a smooth finish as crosscut models and optimize the cutting speed as the ripping blades.

We would recommend them for common DIY projects to make use of the budget and save time on changing multiple blades.

General-Purpose Blades

You might be a bit confused about the combination blades and general-purpose blades. They are all usable for different job types. In fact, their design is different.

Unlike combination models which have every five teeth with clusters, general-purpose blades have 40 or 50 teeth with the Alternating Top Bevel grind and a little alternating face angle. The kerf can also be full or thin, but the gullets are somewhat deeper.

Thin-kerf Blades

Thin kerf is only 3/32 inch compared to ⅛ inch of the full kerf, resulting in the fact that the thin-kerf blades cut less wood than the standard version.

They are suitable for thin-strip ripping projects to save materials and power on every cut.

Dado Blades

If you want to cut joints and grooves to interlock separate parts of shelves, drawer bottoms, or door panels, you will find dado table saw blades helpful.

They come in two different types:

- Stacked blades: More than one cutter and spacer are sandwiched to create a wider cutting profile. As such, the blades can remove a lot of material while ensuring a smooth cutline along the edges.

- Wobble blades: A cheaper and easier-to-set up type to cut wide grooves by spinning through the wood. The blades often support an adjuster to change the cutting width

Whether they are stacked or wobble blades, the number of teeth and the kerf thickness vary from manufacturer to manufacturer.

6 Best Table Saw Blades – Reviews

1. DEWALT DW3106P5 Table Saw Blade

Specifications:

- Blade type: Combination blade

- Material: Carbide

- Cutting type: Crosscuts and rip cuts

- Blade kerf: 0.095 inch

- Blade diameter: 10 inches

- The number of teeth: 60 teeth

- Teeth configuration: Alternate Top Bevel blades (A.T.B.)

We recommend the DEWALT DW3106P5 for D.I.Y. projects because the blades balance quality, performance, and budget-friendliness.

This blade come in a set of two blades: One 32-tooth combination blade and one 60-teeth crosscut blade. Both measure 10 inches in diameter.

That said, the first blade is a combination supposed for everyday cutting projects. However, we would use it for ripping cuts. A 32-tooth blade will remove much material per cutting, leaving inaccurate results.

The second blade with 60 teeth will be more suitable for a detailed crosscut. It can even deal with hard workpieces such as laminate or maple.

We really like their thin kerf of 0.095 inches that allows cutting faster and smoother while minimizing material wastage.

The thin dimension also reduces the vibration as the blades move, and you can expect extra precise cuts in the end.

You might be in two minds about the durability of such a thin kerf. Then, we reveal that the DEWALT 10-Inch Blades are far sturdier than their competitors, thanks to their more rigid tungsten carbide build and steel on the edges. The blades are durable and sharp for a long time.

Nonetheless, you still should not use them on notorious hardwoods. The thin kerf will not cut smoothly.

- Affordable price

- A set of two blades for more tasks

- Tough carbide blades with steel edges

- Clean and precise cuts on standard lumber

- Reduces vibration to improve accuracy with computer-balanced plate

- Able to work with miter saws

- Slow cutting

- Not for extra hardwoods

- Not able to reshape thin blades too many times

2. Freud LM72R010 Heavy-Duty Rip Blade

Specifications::

- Blade type: Ripping blade

- Material: Titanium-Cobalt carbide

- Cutting type: Ripping cuts and also dado cuts

- Blade kerf: 1/8 inch

- Blade diameter: 10 inches

- The number of teeth: 24 teeth

- Teeth configuration: Flat Top (F.T.)

The Freud LM72R010 has a flat-tooth design along with deep gullets, this blade is specially built for wood ripping projects.

Its name implies its cutting purpose. The blade is optimized to rip through both softwoods and extra hardwoods. The rip cuts are almost all ready for gluing with no further sanding or clean-up.

When you run the pieces over the jointer quickly, it might leave a little of a ribbing mark, though. The flat bottom also allows cutting flat dados.

The blade has extra-large flat 24 teeth at the full kerf thickness. There are even anti-vibration hook angle slots in the body of blades to reduce wobbling and noise while you cut wood. A quiet blade means less friction, added smoothness, and more accurate cuts.

Plus, the durability is also excellent. Freud LM72R010 is sturdy and less affected by heat, even on thick workpieces.

This is thanks to its material – a perfect blend of titanium carbide and cobalt that hardly bends or deflects. This profile again backs up its ability to rip hardwood.

Some blades are not exactly ⅛ inch but around 0.126 inches or more. This results in sloppy grooves (if you intend to make groove cuts with this blade).

- Thick and sturdy kerf

- Clean ripping cuts

- Able to cut dado and rabbet

- Affordable price

- Quiet operation

- The wider kerf than the standard

- Not suitable to cut ferrous metals

- Not have I.C.E coating

3. Forrest WW10407125 Woodworker II

Specifications:

- Blade type: Combination blade

- Material: Carbide

- Cutting type: Crosscuts and ripping cuts

- Blade kerf: ⅛ inch

- Blade diameter: 10 inches

- The number of teeth: 40 teeth

- Teeth configuration: Alternate Top Bevel blades (A.T.B.)

The Forrest WW10407125 is quite expensive, but it is worth buying to get professional woodworking projects done with ease.

The blade is also a combination A.T.B. blade as the first DEWALT model. Thus, you can flexibly use the blade for crosscuts and rip cuts without switching the blade.

The upgrades are the material, the number of teeth, and the full-thick kerf.

Specifically, Forrest WW10407125 is made of the hardest C-4 carbide and coated with Teflon. You will not endure wobbling using this blade on even very hard materials. Minor marks are seen but can easily be removed with a slight sanding.

There are 40 teeth rather than 32 teeth like the DEWALT. This number is a good balance to perform both crosscuts and rip cuts with ease. Especially, the kerf is exactly in full ⅛-inch thickness to cut quickly and smoothly.

A high price is the biggest thing that might prevent you from buying, though. But what speaks volumes is Forrest’s customer service.

When we spotted a broken tooth, we decided to ask Forrest for help. And surprisingly, they told us to send back the blade.

They sharpen the blade and replace the broken tooth for free. This saves you a lot and great service.

- Extra sturdy construction

- Can be reshapen many times

- The effective thick kerf on hardwood

- Able to perform crosscuts and rip cuts

- Excellent customer service

- Fewer maintenance thanks to protective coatings

- Expensive price

- Minor marks after cuttings

- High energy consumption

4. Freud D1050X Diablo Table Saw Blade

Specifications:

- Blade type: Combination blade

- Material: Carbide

- Cutting type: Crosscuts and ripping cuts

- Blade kerf: 0.098 inch

- Blade diameter: 10 inches

- The number of teeth: 50 teeth

- Teeth configuration: Alternate Top Bevel blades (A.T.B.)

We will consider another blade from Freud, but it is a combination blade for general-purpose cuttings.

At a glance, this blade looks similar to the Freud LM72R010. In fact, it features more teeth and a thinner kerf to handle every cut rather than ripping hardwood like its brother.

The build quality is unchanged, though. The Freud D1050X has 50 shock-resistant TiCo Hi-Density carbide teeth with laser-cut stabilizer vents.

Also, there is a Perma-Shield external coating to minimize friction and heating generation without weighing down the blade.

The Diablo blade is a combination blade with 50 teeth. This will cut more smoothly and remove fewer materials, which is common for general cutting projects such as siding, framing, or decking.

You can also make crosscuts and rip cuts occasionally, but prepare for possible burning on red oak and the failure to rip dense hardwood.

The kerf of Diablo D1050X is as thin as 0.098 inches instead of being full. This, again, enhances the ability to make precise crosscuts. Unfortunately, thin kerf loses its sharpness quickly than specialized crosscut or rip blades.

Otherwise, the Diablo blade is good for standard projects. If you want to deal with hard workpieces, go for more aggressive models.

- Good perform both ripping and crosscutting projects

- Able to maintain sharpness over time

- Quite and smooth while cutting

- Non-corrosion thanks to the quality coating

- Low power consumption

- Not able to rip dense woods

- More prone to kickback

5. Oshlun SDS-0842 8-Inch Stack Dado Set

Specifications:

- Blade type: Dado blade

- Material: C-4 carbide

- Cutting type: Dado cuts

- Blade kerf: ¼ inch

- Blade diameter: 8 inches

- The number of teeth: 42 teeth

- Teeth configuration: Alternate Top Bevel blades (A.T.B.)

Dado projects such as shelving or cabinet applications often need specialized blades to get the job done; take the Oshlun SDS-0842 8-Inch Dado Blades as the best fit.

Oshlun features a 16-piece stack dado set. With a mix of six chippers, it is supposed to remove large chunks and leave smooth edges.

The outer edge has 42 A.T.B. rip-saw teeth made from the C-4 carbide. As you all know, this material is the hardest metal found on consumer blades for table saws, and the fast and aggressive cuttings are no doubt.

It is worth mentioning that the full-body chippers provide a low-vibration operation to cut to a tee and consume less energy.

The kerf is as thin as ¼ inch and has a standard arbor of ⅝ inch so that you can cut a wide range of dadoes from ¼ to 29/32 inch.

The shim is indicated to be under-sized. It means you cannot add an additional shim to cut the wood narrower, and the cutting results are not completely clean.

We would suggest setting a zero-clearance throat plate, and the finished cuts would be improved. Otherwise, you might spend some minutes sanding the edges before gluing them.

The center hole has a very close tolerance, making the installation and uninstallation a bit hard. However, it ensures that your blade is firmly secure when cutting through thick lumbers.

- Quite fast and aggressive cutting through all types of wood

- Cut various dado sizes

- Able to rip workpieces

- Sturdy and shape teeth

- High materials made of C4 carbide

- Poor packaging

- Not completely clean cuttings

- Need to more time to set up blades

6. Freud D1280X Diablo 12-Inch Table Saw Blade

Specifications:

- Blade type: Crosscut blade

- Material: Hi-density carbide

- Cutting type: Professionally detailed crosscuts

- Blade kerf: 0.118 inch

- Blade diameter: 12 inches

- The number of teeth: 80 teeth

- Teeth configuration: Alternate Top Bevel blades (A.T.B.)

Of all table saw blades on the list, Freud D1280X Diablo is built for large crosscut projects.

The blade is 12 inches in diameter rather than the common 10 inches, and such a dimension allows it to cut a greater depth out of the wood pieces, whether they are softwood or hardwoods.

The material is also improved to the patented TiCo carbide and Titanium to deal with heavy-duty projects. You can expect this cutting tool to have a higher resistance and durability over time.

The non-stick Perma-shield coating is a plus to cut through large pieces with little heat generation.

In addition, its design of 80 teeth sitting next together results in immaculate cuts while minimizing the grabbing experience. The finish is extra clean and ready to use without sanding.

The kerf is what we like about this Freud D1280X. It is 0.118 inches – not too thick to ensure accurate cuts and also not too thin to improve the life of the blades on rough surfaces.

The large size, however, is also a possible disadvantage. Freud D1280X can only work with 12-inch table saws.

- Tri-metal durable teeth for impact-resistant

- Quiet running thanks to laser-cut stabilizer

- Deal with both softwood and hardwood

- Effective and durable thin kerf

- A high number of teeth to cut more smooth

- Heavy-duty patented carbide and titanium

- Easy to install with 7-inch hooks

- Only compatible with 12-inch table saws

- Chipping red paint

- No include arbor knockout to reduce from 1-inch to 5/8 – inch

How To Choose The Best Table Saw Blade

Job Types

Get started by considering your demands and budget for the table saw blade. Most commonly, they depend on particular projects.

For instance, a single combination blade is good for DIYers to make both crosscuts and rip cuts across standard stocks. Regarding specialized carpentry projects, you will want to go for crosscut, ripping, or dado blades.

Crosscut blades such as Freud D1280X are handy to get ultra-smooth and clean cutting edges – good for detailed projects with precision cuts

Ripping blades are good for tough material because they are more durable and with large-gullet cutting teeth – suitable for preparation phases.

Dado blades like Oshlun SDS-0842 are recommended for projects requiring recessed joints and grooves such as furniture, shelving or cabinets.

Blade Quality

We mean the materials of the blades, which decide the lifespan of the blades against frequent cuttings.

Economical blades are often made from thin and stamped steel. They can get the woodworking jobs done several times but will quickly lose their teeth.

Good quality models, in contrast, are carbide metal. Not only do these blades stay durable over time, but they can also be resharpened several times for continual usages.

The coating also affects the blade quality. On low-cost models, coatings are simply painted, and they cannot prevent warping and corrosion.

Instead, you should go for coatings of chrome, Teflon derivative, nickel, or aluminum. These materials can reduce friction and overheat, and good coatings will definitely extend the longevity and performance of the table saw blades.

Blade Kerf

Kerf refers to how wide the table saw blades can cut in the materials. In other words, it indicates the number of wood pieces expended while you cut the lumber.

There are two sizes regarding the blade kerf: The thin kerf and the full kerf.

The thin kerf has 3/32-inch carbide teeth. It cuts the materials with less sawdust and wasted wood with requires less power from the motor.

Thus, the thin kerf is common to rip the workpieces to an exact width. But they are more prone to warp and vibration when cutting through wood.

The full kerf blade, however, is ⅛ inch wide, meaning 1/32 inch thicker than the thin-kerf model. The blade is supposed to be sturdier and less affected by heat – enough to cut the hardwood precisely.

You can use the full-kerf blade on powerful saws with three horsepower or more.

Blade Diameter

Most table saw blades these days are either 12 inches or 10 inches.

What are the differences?

10-inch blades are common due to their ability to sit on many table saws of 10 inches and smaller sizes. They can cut more precisely than larger blades and be less likely to wobble.

12-inch blades, meanwhile, are useful if you desire to cut through very thick boards. Their larger dimension allows cutting a greater depth. Nevertheless, they are more expensive and consume more power to rotate.

Number Of Teeth

The number of teeth is mostly based on the types of table saw blades. For example, crosscut blades often have more teeth than ripping ones. Yet, almost all models range from 24 to 90 teeth.

A rule of thumb is that more teeth offer smoother cuttings with a less likelihood of tearing on the fibers. In drawbacks, they cut more slowly and remove less material.

Blade Teeth Configuration

Configuration refers to the shape of blade teeth, which determine how the blade will cut through the boards. You can choose among the following configurations:

- Flat-Top (F.T.) – Good at quickly cutting through wood. The flat design will rip out materials in large chunks by taking them out of the kerf area. Ragged edges are common. Therefore, they are often ripping blades.

- Alternate Top Bevel (A.T.B.) – Teeth alternate between right and left-facing bevels to produce smooth cuts. They are ideal for making cross cuts and through veneered plywood.

- High Alternate Top Bevel (hi-ATB) – The blades cut like knives with a bigger bevel angle than the standard A.T.B. models. They often use to cut easily-chipping materials with more precision such as Melamine.

- Combination blades (Comb) – As said, these blades are as helpful as crosscut and ripping blades. Their design is the combination of a flat-top blade between four alternate top bevel blades.

- Triple Chip Grind blades (TCG) – They are specialized blades to cut through extra-tough boards such as M.D.F. or Laminates. The teeth alternate between trapeze and raking design so that they remove materials with fewer tears and chips along the edges.

Tooth Gullet

The gullet between teeth is the space that allows removing materials when the blades cut.

Keep in mind that deeper gullets remove boards more quickly and easily found on aggressive ripping blades. In contrast, shallower spaces are designed for precious-cut blades because they remove smaller chips at a time.

Additional Features

These features are not required, but the more – the better. They help improve performance and durability.

- Lubricating coatings allow cutting faster and lengthen the blade life.

- Carbide-tipped blades are from higher-quality materials to cut more aggressively and quickly at the same time.

- Anti-vibration slots between teeth to prevent warping while cutting edges.

One Or Multiple Blades

Each blade might be helpful for specific tasks. A ripping one rips long lumbers effectively, and crosscut blades yield smooth cuts through woods.

You can buy both and use them interchangeably when needed. If you have a limited budget and time to change blades, general-purpose blades get the jobs done acceptably.

Hook Angle

Also known as a rake, the hook angle refers to the tooth face’s angle with the blade’s center.

The smaller hook angle requires more pressure to feed the workpieces. The angle can be negative or positive.

A negative angle is common on blades for circular saws or miter saws tools.

When it comes to table saw blades, a positive hook angle would be better for cutting more aggressively.

The all-purpose blades are somewhere between 15 to 20 degrees; meanwhile, a 20-degree hook angle is specially designed for ripping jobs.

Anti-kickback Shoulders

If you focus on ripping workpieces, you should invest in blades with anti-kickback shoulders. They are a non-cutting part that will protrude out behind the teeth.

The purpose is to force a slower feed rate of piece wood and reduce kickback, meaning you cut a less amount of material by each tooth.

Tips When Use A Table Saw Blade

You must know your table saw and your cutting purposes very well to install and use the blades properly.

- Always check the specifications of blades and recommendations of the manufacturers carefully to make sure the blades work with your table saws.

- Make sure the blades are sharp and straight when installed into the saws. Wobbled or loosened blades can ruin your cuts and even cause kick-back accidents.

- Strictly adhere to workspace safety precautions: choosing a suitable blade for the projects; wearing protective gear; keeping your hands off a moving blade; adjusting the fence carefully; using an outfeed table for longboards, etc.

- Learning the techniques of crosscut and ripping cuts to move the blades correctly and securely.

Frequently Asked Questions About Table Saw Blade

Why Is Table Saw Blade Important?

Table saw blades are often complicated, and they have different designs to optimize cuttings through various materials.

Using wrong blades can end up unprecious or ragged cuts. Even worse, it can lead to serious cutting injuries.

Most commonly, table saw blades are named for either their types or applicable cutting projects for your reference.

How High Should I Set My Table Saw Blade?

It depends on the blade types, job types, and materials, but you can refer to the following three heights.

- The safest cutting height: Ideally, the teeth’ blade should be ⅛ inch over the cutting boards.

- Manufacturer’s recommended height: It is suggested by many manufacturers that you should have 5-7 teeth when crossing cut the workpiece and 3-5 teeth when ripping it.

- Higher heights: Advantages of setting the blade at higher heights are a lesser strain on the motor and less likelihood of heat generation.

Can I Sharpen The Table Saw Blade?

Blades will eventually reduce their cutting effectiveness. The symptoms are tougher cuts, chips, more stressful cutting feeling, etc. It is time to sharpen blades.

Some low-cost blades cannot be sharpened, unfortunately. You must choose high-quality blades with thick teeth. Then, you can resharpen them five or ten times.

How To Sharpen The Table Saw Blade?

Wear protective equipment and be ready to sharpen the blade by one of the three standard methods:

- Taper File: Secure the blade. Put your dominant hand at the base and the other hand on the tips. Use two strokes of the taper file for each gullet.

- Crank Sharpener: No particular skills are required. You simply insert the sharpener over the chain, winding the handle so that the sharpener will grip the chain. Pull it toward the blade at a degree of 25 or 30.

- Automatic Sharpener: Insert the chain of table saw blades in the sharpener and shut the lid. Turn the saw on and give it several revs. Push the tip against a flat surface so that the sharpening block will contact the teeth and get the job done.

How To Make Dado Cuts With Table Saw Blades?

Dado blades are designed to complete dado cuts with extra precision and efficiency.

- Unplug the power source of your saw

- Set the blade to a specific correct height. You can go half of the board’s thickness when it comes to dado cuts.

- Ensure a distance between the rip fence and the blade to put the cutting board.

- Move the board through the blades to create the first dado cut.

- Repeat the second pass but move the fence around 1/4 inch from the first cut.

- Collect the cuts at the rear end.

If you’re still up in the air, consider watching this:

How To Change Table Saw Blade?

Although high-quality blades can be resharpened, they will eventually wobble and be unable to cut. That time, learn steps to change a table saw blade:

- Disconnect the power source to the table saw

- Unassemble the throat plate, as well as the blade guard

- Raise the table saw blade to the maximum height

- Use a pair of wrenches to loosen the blade’s arbor nut

- Remove the nut carefully with your hands

- Take the blade out and insert a new one

- Replace both the arbor nut and the washer

- Tighten the nut

- Complete with replacing the blade guard and throat plate

Can I Put A 12-inch Blade On A10-inch Table Saw?

No. The 10-inch saws do not comfortably accept the much 12-inch blades. Moreover, the 12-inch blades require more power to rotate and cut. Meanwhile, 10-inch saws will work under their power.

Which Is The Best Way To Clean A Table Saw Blade?

We would suggest using caustic oven cleaners. Their main ingredient is sodium hydroxide or potassium hydroxide. It can burn away dirt, carbon, and loosen residue easily on the blade. However, must use gloves when using those cleaners.

Conclusion

All in all, Forrest WW10407125 is our choice for the best table saw blade, considering its ability to deal with both crosscut and ripping applications along with great customer service.

Moreover, its quality build and stable performance ensure a high chance of smooth and accurate cuts.

You can also choose Freud LM72R010 for ripping or Freud D1280X for crosscut jobs with a lower budget. They are specially built to do different cutting jobs efficiently.

Other blades on the list are also worth checking. However, whatever you choose in the end, take the cutting purposes, blade quality, kerf, and teeth configuration in mind. They are some of the most critical factors in choosing the table saw blade.

![9 Best Pole Saws of 2023 [Ultimate Guide] 9 Best Pole Saws of 2023 [Ultimate Guide]](https://handykeen.b-cdn.net/wp-content/uploads/2021/03/best-pole-saw-300x200.jpg)