Not all carpenters have a wide workshop to store a stationary jointer. They use benchtop jointers as an alternative. This power tool is more compact but provides almost the same efficiency.

The manufacturers always apply new technologies in building benchtop jointers.

That’s why many models have different features. You will need more experience to choose the right benchtop jointer for your needs.

In this article, we explain all the features of the top 5 products on the market and a detailed buying guide.

Read on to find the best benchtop jointer for you!

Table of Contents

Top Rated Benchtop Jointers Comparison

Benefits of Benchtop Jointer

You can have a lot of benefits using a benchtop jointer. Regardless of the small size, the power tool can support you in completing multiple woodworking projects.

The main job of a benchtop jointer is to plan board edges. With the help of this powerful tool, you can easily prepare suitable wood pieces for building cabinets and tabletops.

Besides the primary function, a benchtop jointer also supports in:

- Straightening an edge of a curved board

- Getting rid of saw marks on the edge of a board cut

- Creating bevel edges for doors and boards

- Flattening warped faces of boards

- Trimming stock fractions from doors and windows.

- Planning cabinet door edges to micro sizes

- Cleaning up the glue joints remaining on laminated boards

- Making edges of the plywood and particle-board smooth

5 Best Benchtop Jointers – Reviews

1. PORTER-CABLE Benchtop Jointer (PC160JT)

Specifications:

- Type of cutter head: Straight knives

- Number of knives: 2

- Cutting capacity: 6 inches

- Cuts per minute: 12,000 to 22,000

- Cutter head diameter: 3 inches

- Dimensions (LxWxH): 32.1 x 12.4 x 11.2 inches

- Revolution per minute: 6,000 to 11,000 RPM

- Motor power: 10 amps

- Dust collection: Yes

- Weight: 35 pounds

We are impressed by the variable speed options of the PORTER-CABLE PC160JT. You can slow the motor operation to only 6,000 RPM or increase the speed up to 11,000 RPM, depending on the mass of your project and the size of the wood.

Of course, as the speed changes, the number of cuts per minute will be adjusted as well. When the engine works at 6,000 RPM, the 2 straight blades can perform 12,000 cuts within 1 minute.

This number of cuts is 22,000 at 11,000 RPM – the highest cutting speed a benchtop jointer can offer among 5 products.

This PC160JT model is easy to use right out of the box. The manufacturers give a full manual about installation, settings, usage, and replacement in the package. They even install the safety guard on the cutter so that you will not have to do this job.

Before putting the piece of wood on the infeed, make sure that you align the correct cutting angle. The fence of this jointer is tiltable to 45 degrees. You can also customize the cutting depth as you desire by adjusting the knives.

It is quite simple to align the knives. You just need to use the built-in jackscrew knife leveling arrangement system to loosen and adjust the blade. As you find a suitable depth, stabilize the 2 knives with the help of the built-in cutter head lock.

We give a minus point to the dust chute vac adapter. It does not seem to provide a proper connection. The sucking power is not stable, and sometimes the collection system gets clogged during work.

- Variable speed to process types of different wood sizes

- Easy to find replacements for worn-out components

- Suitable for flattening, edging, and face jointing

- Large table size with a 30-inch length supports holding a long workpiece

- The durable fence made of aluminum offers a tight lock on the wood

- Lightweight and high portability

- Dust chute vac adapter not making proper connection

- Short infeed table leads to difficulty in expansion

- Can not make the bevel cuts

2. WEN 6559 Corded Benchtop Jointer

Specifications:

- Type of cutter head: Straight knives

- Number of knives: 2

- Cutting capacity: 6 inches

- Cuts per minute: 20,000

- Cutter head diameter: 6-1/8 inch

- Table size: 6-1/4 x 28-½ inches

- Dimensions (LxWxH): 32 x 14.5 x 11 inches

- Revolution per minute: 10,000

- Motor power: 10 amps

- Dust collection: Yes

- Weight: 36.4 pounds

The WEN 6559 comes with a powerful motor that works at a high power of 10 amps. With 20,000 cuts per minute, this device shows its advantage when it comes to quick and smooth cuts.

Among 5 products on this list, the WEN 6559 model only stands behind the PORTER-CABLE PC160JT for the highest cutting speed.

The fast speed is not only for straight cuts but also for bevel cuts. You can adjust the bevel angle of the 20-¾ x 4-½ fence up to 45 degrees to either the left side or right side.

There should be no worry about inaccurate adjustments, as the onboard depth scale guides you to the right angle you need to align.

Even beginners can control this jointer with ease. The dimension of 32 x 14.5 x 11 inches and weight of 36.4 pounds make the machine heavy enough to stay stable during a long-session working period but not reduce its portability.

To plan your workpiece, push it from the infeed table through the 2 straight blades in the middle to the outfeed. It is very safe and easy to plan the board.

The safeguard only gets out of the way when the piece of wood comes to the cutter and will cover the blades back after the board comes to the outfeed. This design is for preventing accidental injuries.

Another thing that may save your finger is the included push stick in the package. We all know about its helpful role.

Otherwise, the powerful motor offers quick cuts, but it also gets hot very quickly. If you don’t let the machine rest, the overheating issue will reduce the durability of the jointer.

- Easy to adjust the two-knife cutter head

- Dust collection works efficiently

- Easy assemble and set up

- Filter bag offers minimal cleanup

- Cut wood very smoothly and flat surfaces

- Affordable price

- The base is very easy to grate

- Quite noisy

- Not suitable for planning big boards of woods

3. Wahuda Benchtop Wood Jointer (50180CC-WHD)

Specifications:

- Type of cutter head: Spiral cutter head inserts

- Number of knives: 16

- Cutting capacity: 8 inches

- Table size: 8 x 33 ½ inches (Extendable to 51 inches)

- Revolution per minute: 12,000 RPM

- Motor power: 10 amps

- Dust collection: Yes

- Weight: 49.9 pounds

Like the 2 previous models, the Wahuda Tools 50180CC-WHD is equipped with a powerful 10-amp motor. But what makes this jointer more outstanding than the 2 others is the high speed of 12,000 RPM, the high cutting capacity of 8 inches, and the large expandable base.

The table size of 8 x 33 ½ inches is good for holding a piece that is 8 inches wide and 33.5 inches long. But there is no issue if you place a larger material on the surface. Just loosen the lock and expand the table length to up to 51 inches.

The capacity of 8 inches allows the benchtop jointer to do different heavy-duty tasks with any large board. We try using this 50180CC-WHD for handling edges, jointing, flattening, and tapering uneven lumber. The result is great as the board surface is clean and smooth.

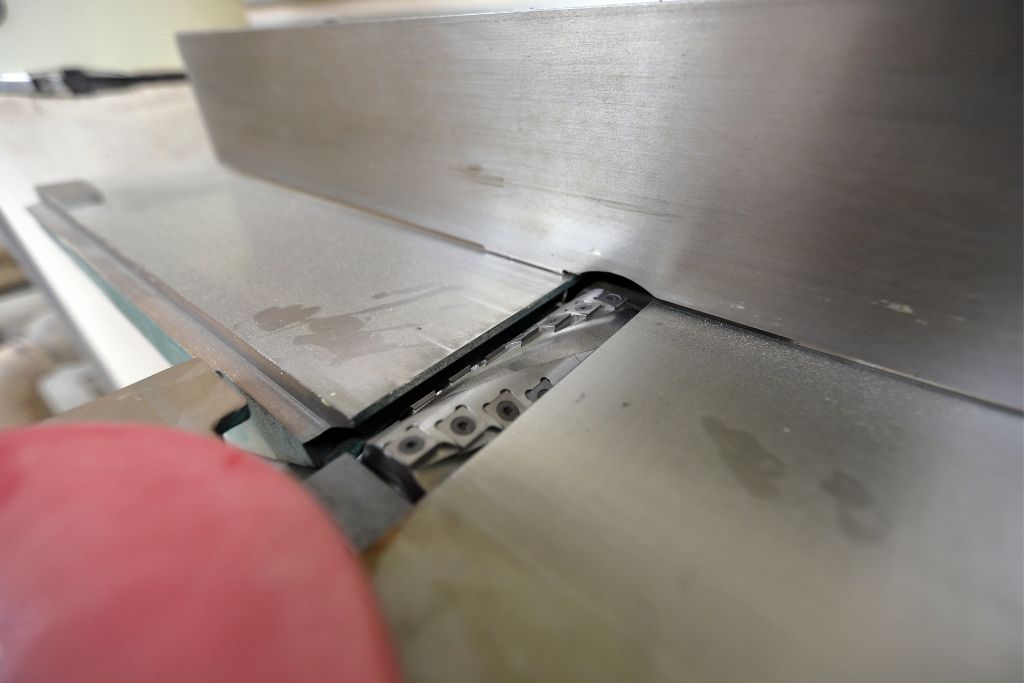

The type of knives is a big difference between the Wahuda Tools jointer and the 2 first devices. This 50180CC-WHD does not use 2 straight blades but 16 4-sided spiral carbide inserts.

As you know, spiral blades provide smoother, quieter, and sharper cuts on the material.

The spiral Wahuda Tools jointer is not worse than the 2 straight-blade models when it comes to ease of use. But you may feel the 50180CC-WHD is easier to maintain.

While the straight machine requires you to take out the entire blade system to change the blade, the spiral type does not need to be detached for maintenance. You only have to change the dull tips among 16 inserts on the cutter shaft using a T-Torx wrench included in the package.

The Wahuda Tools 50180CC-WHD is great for big projects. But it may not please you at best when you need to do mini tasks. It is a miss that the motor speed is fixed at 12,000 RPM. No variable system helps you slow down the blade to cut thin boards.

- The motor is quiet while running

- No vibration during work

- Adjustable and expandable cast iron tables enhance stability

- Cost-saving for maintenance, as only dull inserts are needed to replace

- Handling a variety of woodworking, such as squaring, tapering, and trimming

- Fence adjustments to 90 degrees and 135 degrees for versatile wood planning

- The fixed speed reduces the flexibility of the jointer

- Inaccurate depth gauge

- Quite expensive

- Required experienced carpenters for planing thin wood pieces (as the speed is fixed at a high rate

4. CRAFTSMAN Benchtop Jointer (CMEW020)

Specifications:

- Type of cutter head: Straight knives

- Number of knives: 2

- Cutting capacity: 6 inches

- Cuts per minute: 12,000 to 22,000

- Table size: 6.5 x 30 inches

- Revolution per minute: 6,000 – 11,000

- Motor power: 10 amps

- Dust collection: Yes

- Weight: 35 pounds

The CRAFTSMAN CMEW020 features a variable speed range like the WEN 6559 does. You can adjust the engine from 6,000 RPM to 11,000 RPM to customize the number of cuts, which is 12,000 at minimum and 22,000 at maximum.

Regardless of the thickness and hardness of the material, you can make flawless cuts using this CMEW020.

Although the capacity of this machine is 6 inches, you can still rely on this jointer to do medium or large projects. This model is different from all the other 4 models because of the removable sidebar.

If your wood is wider than 6 inches, you can detach the wall to place it balanced on the table surface.

You can’t use the device right after unboxing the package, as the fence does not stay square to the table surface. You need to spend time tuning and tightening this equipment in the correct position.

The adjustment may be a little bit long but not difficult. On the positive side, since the product is adjusted correctly, it will retain the change after multiple cutting turns.

The operation is not so tricky. Even a newbie can easily move the wood from the infeed to the outfeed. The table surface is so flat and smooth. You can push the board through the blades without worrying about it getting stuck.

On the downside, we are not pleased with the noise of the motor. The operation seems to be quiet in the beginning. But after running for a few hours, the noise starts to get louder.

- Easy replacement and knife adjustments

- Great for edging, flattening, or face jointing

- A long period of warranty to 3 years

- Compact size and lightweight

- Safety power switch lock stops the jointer immediately in emergencies

- The motor gets louder and rattle after a period of operation

- Lack of rabbeting feature

- No dust collection bag

5. RIKON Power Tools 20-600H Benchtop Jointer

Specifications:

- Type of cutter head: Helical head inserts

- Number of knives: 12

- Cutting capacity: 6 inches

- Cuts per minute: 12,000

- Cutter head diameter: 2 inches

- Table size: 30 x 6-3/16 inches

- Revolution per minute: 20,000 RPM

- Motor power: 10 amps

- Dust collection: Yes

- Weight: 36 pounds

We recommend this model for beginners, as it is easy to use and safe. The machine appears assembled. You only need to spend a few minutes aligning the fence. And the device is ready for operation.

The way of usage is similar to how you manage the 4 previous models. Just push the board from the infeed, through the helical blades, to the outfeed.

There will be no direct contact between your hands and the knives, as you can use the 2 push blocks (included in the package) to move the wood board.

Unlike the 4 previous jointers, only this model features a 6-row helical cutter head with 12 2-sides inserts. It is better at handling heavily figured wood or reversing grain than straight knives. Compared to spiral cutters, it is more suitable for hardwood but does not last as long.

It is not required to disassemble the entire blade system to replace the dull edges. You only need to use the included hex wrench to rotate the blade shaft until the dull inserts show up. And then, replace the worn-out inserts with new ones.

The RIKON company has successfully designed the adjustable tiltable fence for this model. You can adjust the table to 2 common angles, which are 45 degrees and 90 degrees. In both these 2 positions, the cutter offers smooth and accurate cuts.

The dust collection system does not have our trust, as it gets clogged very easily. But you don’t have to worry too much as we have a solution to fix this issue.

Whenever the dust chute clogs, just pop off the cover and vacuum the sawdust out. The equipment will work properly again.

- It is easy to adjust the knifes

- The all-metal construction lasts over a long period of time

- Quick depth setting mechanism with an accurate scale

- The longest warranty period of 5 years

- Access quickly on/off switch

- Dust chute sometimes gets clogged

- Not suitable for big projects

- The locking mechanism is not tight sometimes

Things To Consider When Choosing The Best Benchtop Jointer

Power

If you want to complete the jobs quickly and efficiently, a powerful jointer is required. How to know if your device is strong or not? Check the amperage of the engine.

The benchtop jointers are usually equipped with 10-amp or 15-amp motors. The engine can deliver high power to run the blades at high RPM (revolution per minute) to make smooth cuts.

Cutter Head Style

A benchtop jointer has 3 main types of cutter heads, which are:

- Straight Knives

This cutter head has straight knives with sharp lines, as the name describes. The WEN 6559 model has this type of cutter head.

The straight knives are the most affordable cutter head style. Of course, the low price does not mean low efficiency. You can place your trust in a benchtop jointer with straight knives to help you with basic tasks.

The main material of straight knives is usually solid steel. It is durable and sturdy that can remain functional after multiple planning turns on many objects, such as foam, metal, plastic, wood.

On the downside, straight knives are a little bit difficult to replace and install. You will need a lot of patience to align the knives in the correct position. In addition, the straight knives often create more noise during operation.

- Spiral Cutters

Spiral cutters feature many sharp knives that are positioned in spiral lines around a central shaft. Each square knife is perpendicular to the feed direction.

Most carpenters choose spiral inserts instead of straight knives. These pieces of equipment are simple to sharpen and quiet during work.

The great thing about spiral inserts is the low requirement for replacement. The carpenter needs to spin the equipment to change the new edge whenever an edge is dull.

As all the sides become dull, the inserts can be detached and quickly re-sharpened.

The material of spiral cutter heads is usually tungsten carbide. The head is ideal for working with soft and low-density materials, including plastic, wood, and foam.

The only drawback of spiral inserts is, they are more expensive than straight knives. But as people often say, you get what you pay for.

- Helical Cutters

A helical cutter is similar to the above cutter, but its square blades are angled to the incoming workpiece.

The head contains durable carbide teeth made of steel. It is solid enough to perform smooth planning on hard objects, including metals, hardwood, etc. If you often work with these materials, you may want the RIKON model.

Unfortunately, helical heads can not beat spiral heads at the number of contact points. This means they require more blades to make cuts on deep holes. Of course, the more blades used to cut, the quicker they become dull.

Capacity

The capacity describes which size of the workpiece the gadget can flatten. The maximum capacity is determined by measuring from the table edge to the start of the fence. You can adjust a lower capacity to work on a small workpiece.

Popular benchtop jointers have the 4 following capacities:

- 6 inches

- 8 inches

- 10 inches

- 12 inches

- 16 inches

Of course, the jointer is more flexible if it has a high capacity. But we don’t advise you to get a machine that does more than what you need. The reason is, the higher the capacity, the more expensive the device is.

Beginners who work with small projects usually require a capacity of 6 – 8 inches. Professionals who work in large workshops may need a higher capacity.

Dust Collection

Sawdust is the most annoying thing any carpenter has while using a jointer. No one wants to spend time cleaning the working mess. That’s why a dust collection system is necessary in this case.

The collector is designed with a vacuum that can suck the dust automatically and store it in a dust bag. After the job, you can take the bag out and throw the waste away.

All models nowadays come with this cleaning system. But you should ask the seller to see whether the dust port that can connect to your shop vac and dust bag are included in the package or not.

The Fence

You can consider the fence a metal wall located on one side of the benchtop jointer. This component works to keep the workpiece stable while you push it through the cutter.

On the other hand, you can look at the difference in height between the fence and your material to see how flat it has become.

Most adjustable fences appear with positive stops, which help align the wood piece in fixed angles, including 45 degrees, 90 degrees, and 135 degrees.

Keep in mind that some benchtop jointers do not include two positive stops. They will have one for 45 degrees or 90 degrees. The popular is at 90 degrees.

Table

The table is where you put the wood piece on. It needs to be flat and parallel to the blade. Otherwise, if the table surface is tilted, you may not be able to do smooth and straight planning for your material.

Also, you should choose the extendable table. If the table can be extended on 2 sides, it can support a large workpiece.

Mobility

It is essential to look for the mobility of a benchtop jointer. As you know, the gadget is specially designed for carpenters who have tight spaces. The machine should be easy to move around in the workshop.

Several jointers come up with pre-installed wheels. You just need to push the machine to bring it to the place you need.

However, some models don’t feature wheels. This means you will need to purchase the equipment separately and find a way to install it to the gadget.

Safety Features

There were many carpenters who got injured using a benchtop jointer. Therefore, we require some safety features in the device.

The lock mechanism seems to be the most common safety equipment. It helps lock the workpiece in place. When you push the material to the blade, it will slide under your control.

Another safety feature is the guard. It covers the blade when you do not use it. As you push the wood to the knife, the guard will automatically open and close after you complete the flattening jobs.

Besides, a benchtop may come with more safety systems, such as a trigger for a quick shutdown system.

Cutting Depth

This is an important factor to achieve a straight board at the number of passes. At the larger depth, you will make fewer passes to straighten wood.

Some says a depth of 1/6 inches is enough for all tasks. Others prefer their knives stay at the 1/32-inch and 1/2-inch mark. Most models cover up to 1/8 inches of depth.

What you should look for is a detail and accurate depth adjustment system. The more marks the depth pointer has, the better it is for you.

It is even better if you can easily adjust it with onboard depth scale before each pass. In this way, you can run test cuts and tune it if necessary.

Cutter Head Speed

The speed of a benchtop jointer is determined by how many cuts the blade can perform in 1 minute. The faster the blade, the smoother it can cut.

A good benchtop jointer should make 6,000 to 11,000 cuts for a single minute. High-quality models can even make 12,000 to 20,000 cuts per minute.

Setup

Several jointers come assembled, but some don’t.

Although the setup does not affect the functions, it is still better to have a machine that is ready to use right out of the box.

Anyway, if the manufacturers do not install the machine, ensure that it comes with good installation instructions.

An easy-to-understand guide is essential for beginners who are getting used to benchtop jointers.

Additional Features

You may look for some additional features too. They often cost extra but will make your work easier.

As mentioned above, an adjustment mechanism for the fence is a nice touch. A few positive stops to go with it is even better. These features make flattening angled boards more convenient.

Another feature you may need is a speed variable dial. It helps you control the spinning speed of the motor and, in turn, adjust the cuts per munite index.

With the help of the adjustable dial, you can change the machine to suit the requiements of your workpieces.

Some of the models have additional feature extendable wings 2 sides for benchtop jointers. This allows you to pass longer workpieces to process.

There are models with a built-in planing feature. To achieve this effect, they an open area under the cutter head and an adjustable feeding table.

If you put a board neatly between these two components, you will have a consistent thickness across the board.

Tips When Use A Benchtop Jointer

Tips For Operating A Jointer

Beginners may not know how to use a benchtop jointer correctly. Thus, we will share some useful tips to help you control the device.

Always follow the below tips:

- Tune the jointer to suit your workpiece. If you don’t have tuning experience, you can choose the default settings.

- Clamp down both ends of the fence while doing adjustment for the 90 degrees position.

- Set up the upper limitation and cutting depth. Many jointers have depth scale. Use it to monitor the depth of cut.

- Prepare the cutting depth at 1/16 inches or lower on the table before switching the system on.

- Do a few test cuts to ensure your depth pointer is correct.

- Determine which edges of the wooden boards that will be jointed. You can leave a mark on the edges.

- Grip the wood board and push it towards the cutter blade to plan it. If you just want to work with the edge, keep a firm pressure downward on the base and sideways along the fence.

- If you want to make a curved edge straight, plan some inches from one end until you notice the blade loses contact with the cupped edge, lift the material, and plan the other end.

- Check the set screws that hold the knives in the cutter head regularly. The screws may become loosened after a period of time.

- Replace the knives on the blade regularly to keep the machine efficient at all times.

- Do not adjust out-feed table

Safety Tips For Using Benchtop Jointers

It is good if your jointer has safety components. But it does not mean you don’t need to protect yourself. It is still recommended to remember and follow the safety tips below:

- Never detach the swiveling blade guard

- Keep your fingers as far from the cutter head as possible

- Don’t try to push materials that are too short. The short workpiece may increase the risks of hand cutting.

- Use a push block instead of bare hands to push the board

- Stand to the left side of the device and behind the cutter blade

- Stabilize and lock the workpiece in its position before starting planning

- Wear safety glasses and ear-protection equipment

- Avoid loose clothing or long sleeves when starting the work

- Always check the depth of cut before you begin jointer

FAQs About Benchtop Jointer

How Does Jointer Work?

When a jointer works, it spins its cutter head between a 2-part infeed-outfeed table. You push your board from the infeed table surface through the sharp edges of the spinning blades to the outfeed surface.

When the board gets in contact with the blade, the sharp edges will quickly plan its bottom to provide a smooth and flat surface.

You are able to adjust the infeed table up and down for the customized cutting depth. The fence keeps the board at a stable position, preventing it from slipping.

How Do I Know What Size Of Benchtop Jointer I Need?

The size of the benchtop jointer is measured from the table edge to the start of the fence. The distance between these 2 points tells the size of wood that can fit the machine.

Before buying, you need to measure the width of the workpiece you are about to plan. After that, buy a jointer that features a size that is similar to or larger than that measured width.

For example, the width of the wood is 6 inches. You should buy a benchtop jointer with a size of 6 or 8 inches.

How To Set Up A Bench Jointer?

A benchtop jointer can work accurately if it is set up correctly. However, most newbies don’t know the right way to install and adjust the device to suit their projects.

That’s why we will explain the 5 basic steps for bench jointer settings.

- Check the tables to see whether they are aligned parallel to the cutter head or not.

- Make the fence square to prepare for square cuts

- Set up the blades in the correct position in the cutter head

- Align the outfeed table

- Test the adjustments

How To Adjust A Jointer?

- Adjust The Fence And Infeed Table

You need to loosen the stop screw in the fence using a wrench. By doing this, you can rotate the fence until it stays in a perpendicular position to the knife.

It is recommended to use a framing square to check the angle. Make sure that it is 90 degrees.

After that, you can loosen a lever located under the table to align the infeed table. This work is for aligning the cutting depth.

When everything is completed, tighten all the screws to keep the fence and infeed table stable in their places.

- Adjust The Outfeed Table And The Blades

You have to rotate the knob under the table to move the outfeed table up and down. We advise you to use a straightedge to keep the outfeed table even with the top of the knives.

There are screws above the blades. Loosen them and adjust the knives to the right angles and positions. And then, tighten all the screws back.

How To Clean A Benchtop Jointer?

Most modern benchtop jointers nowadays feature dust collection systems. The cleaning equipment will automatically suck all dust and wood waste and put them into a dustbag.

As you complete your projects, you can throw all the trash in the bag away.

In case your jointer does not have a cleaning system, you can use a handheld vacuum machine to suck all the dust on the machine. Also, you can use a small brush to remove the dust clogging in hard-to-reach areas on the jointer.

Please make sure that you don’t plug the machine into the power source while cleaning. If the blade runs, it may damage you.

How Much Does It Cost To Maintain A Benchtop Jointer?

The cost for maintaining a benchtop jointer depends on the number of components and types of materials. But overall, the cost is no more than maintaining a drill device.

We advise you to maintain the jointer regularly. The price for maintenance is a lot cheaper than the cost of fixing or replacing broken components.

How Do You Maintain A Benchtop Jointer?

Always check, change the old knives and attach the new ones. Of course, maintenance is not only about changing the blade. It is also about cleaning and lubricating.

You can use a vacuum or compressed air to get rid of all wood waste on the machine, clean out rollers and the head cutter. Dust can fall into any component and cause clogging issue, which leads to durability reduction.

You should lubricate the table to make it smooth. Remember that you will push the wood from the infeed table to the outfeed. If the table is not lubricated, it may be difficult to push the material on a straight line.

Replace the engine, as well as other safety systems regularly. After years of use, you should change these parts.

Conclusion

We have shared with you our 5 best benchtop jointers on the market. What is your choice?

The best benchtop jointer overall is the PORTER-CABLE PC160JT.

This model features a variable RPM speed range from 6,000 RPM to 11,000 RPM, allowing you to set the blade power that suits the thickness and hardness of the material you are about to cut.

Its safety guard makes sure that there will be no accidents that lead to serious injuries.

This machine offers a fence that can be tilted for flexible cuts at multiple angles. Not many models allow you to set up the fence up to 45 degrees. You are also easy to change depth of cut.

The thing that makes this PC160JT stand out is, it is highly easy to use. The manufacturer gives a full instructions that beginners and experts can understand and manage the machine quickly after unboxing it.

The model on the second position is Wahuda Tools (50180CC-WHD). This model features high cutting capacity of 8 inches.

Plus, the 16 4-sides spiral carbide inserts will offer flawless cuts on any type of rough materials. You can consider them as a great partner for any big project.

We like the flexibility of the Wahuda Tools model. It can be used for handling edges, jointing, flattening, and tapering uneven woods. Although you put the blade under high operation pressure, low maintenance is required.

Anyway, the decision is yours. Make sure that you follow our instructions in the buying guide. All the factors that we have explained will help you pick out the suitable models for your requirements.

![9 Best Pole Saws of 2023 [Ultimate Guide] 9 Best Pole Saws of 2023 [Ultimate Guide]](https://handykeen.b-cdn.net/wp-content/uploads/2021/03/best-pole-saw-300x200.jpg)